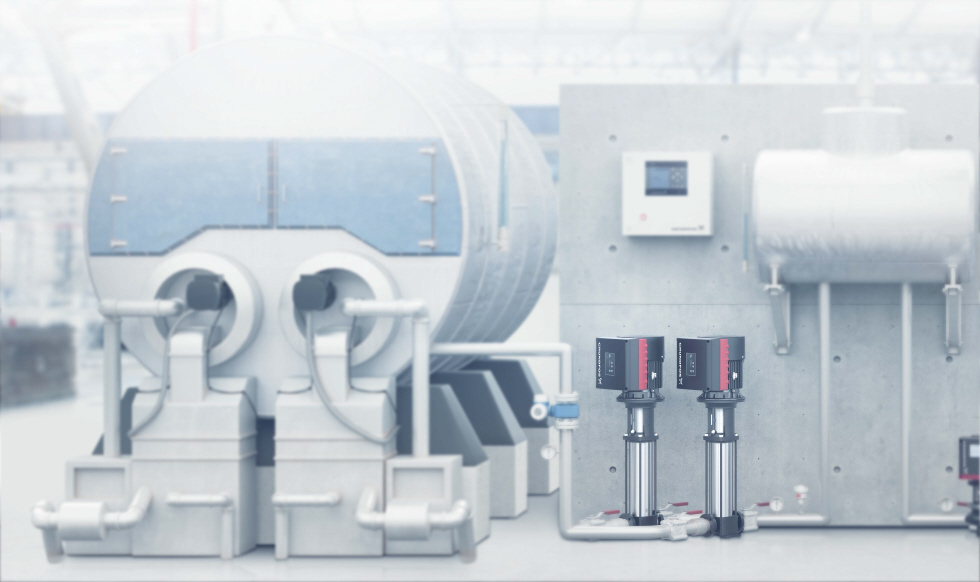

Production lines depend heavily on efficient and reliable boiler operation. This is why Grundfos’ robust feeding pumps for steam boilers, hot water boilers and thermal oil boilers have been specially designed to offer optimum performance in even the most extreme conditions.

All Grundfos feeding pumps can be fitted with an integrated frequency converter to optimise processes in terms of temperature, pressure level and quality of steam. If make up of the water is part of the process, dosing pumps will ensure highly accurate dosing of any additive.

Steam: When it comes to feeding pumps, steam boilers are among the harshest and most challenging applications. The process involves high pressure, high ambient temperatures and a significant number of starts and stops that stress the pump. To accommodate the extreme conditions, Grundfos’ multistage feeding pumps have been optimised in every aspect and are even capable of efficiently handling poor inlet conditions. The pumps can further be supplied with an air-cooled top that protects the shaft from any damage caused by the high temperatures – and with a monitor that will supervise the process and warn you about any deviances.

Hot water: Grundfos’ single-stage shunt pumps for hot water boilers handle temperatures up to 110°C, ensuring that any process requiring hot water is sufficiently supplied – and that the water temperature in the boiler is constant.

Thermal oil: Thermal oil is a highly suitable alternative to steam in many processes, particularly where very high pressure is required. Grundfos’ range of feeding pumps for thermal oil applications handles temperatures up to 240°C and comprises both single-stage and multistage models.